#Motor torque calculator code

NEMA Code Letters are provided below for easy reference. Design D motors are available in 5-8 slip and 8 to 13 slip. The above calculation is the torque equation. Design D: These motors have very high starting torque, high slip and low starting current. Gear Reducer Torque 9550 Motor power / Rated Power motors input revolutionRatio gear reducer efficiency. These motors can be used for hard to start loads.

#Motor torque calculator full

Note that should this be the stall torque, the arm would not be able to lift itself at full extension with a payload. Design C: These motors have high starting torque, low starting current and low slip. Here useful converted relationship to Output torque’s unit : 100 N.m 10.1972 Kg.m: 100 N.m 885.07457 9349 Ibs in: 100N.m 885.07458 ibf. Join our motion control specialist, RJ Ruberti, who can help you derive a formula that can calculate motor. Motor power torque ÷ 9550 × Rated power‘s motor input speed /Ratio /service factor.

The torque shown is the RATED TORQUE you can use for your search. The above calculation is the torque equation. Note the numbering starts with the extremity of the arm, so the final torque is the one lifting the entire arm (start from A1 being the load you wish to carry at full reach.). A DC motor torque calculator is a tool used to calculate the torque of a DC motor based on its electrical and physical characteristics. Use the image above to help you determine which torque corresponds to which joint. Tm CALCULATE CALCULATE Home Engineering Electrical DC motor armature mechanical torque (Tm) calculator- step by step calculation, formula & solved example problem to find the armature mechanical torque produced by an electrical DC motor. A1: can represent the load being lifted.

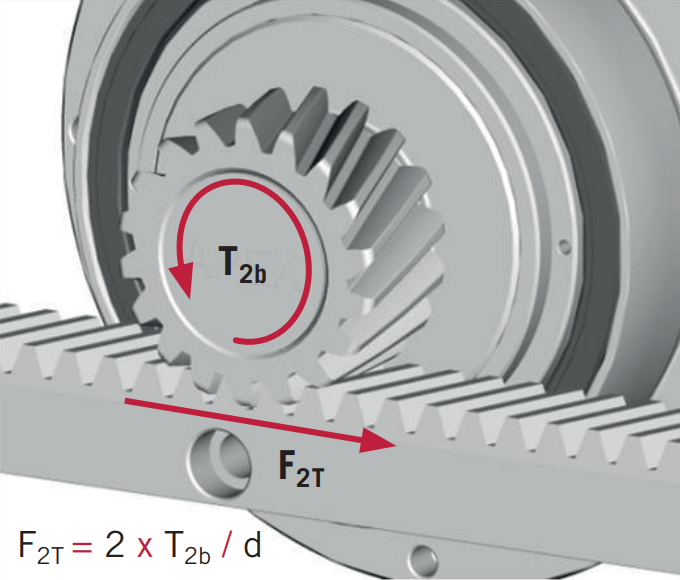

n r rated rotational speed (rev/min, rpm) In metric units the rated torque can be expressed as. Take a look at the Robot Arm Torque Tutorial for more information. T full load torque (lb ft) P hp rated horsepower. The most common units are kg-cm and oz-in. To calculate load torque, multiply the force (F) by the distance away from the rotational axis, which is the radius of the pulley (r).

The torque (T) required at each joint is calculated as a worst-case scenario (lifting weight at 90 degrees). The formula below is used to find the required motor. The Robot Torque Arm Calculator is intended to help you choose the right motor for each joint of your robotic arm. It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust.

0 kommentar(er)

0 kommentar(er)